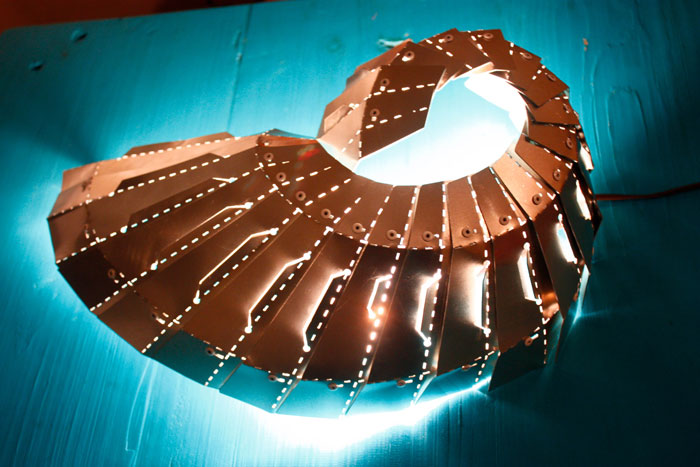

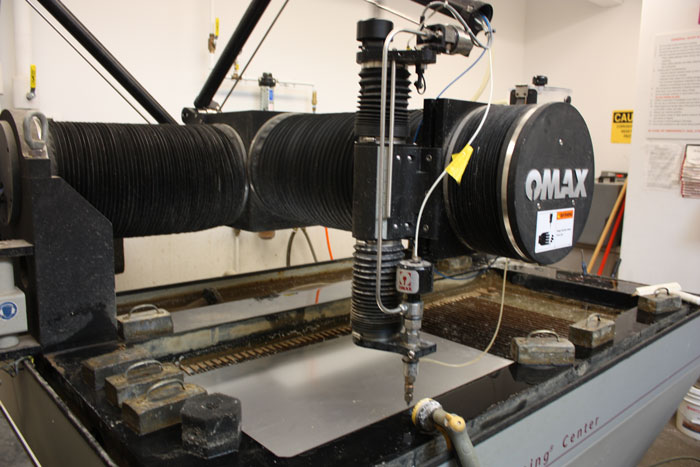

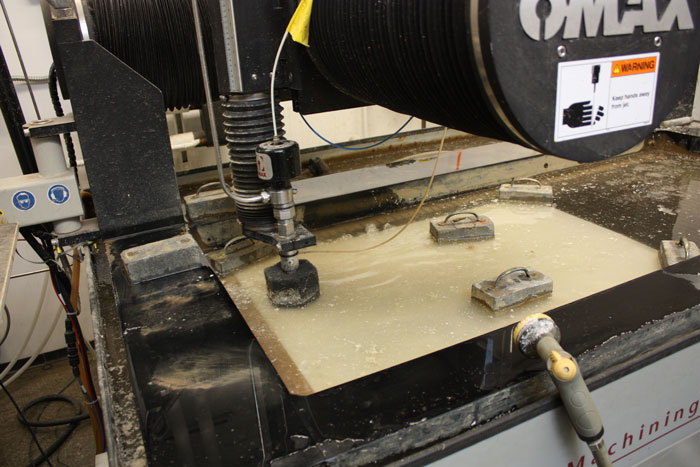

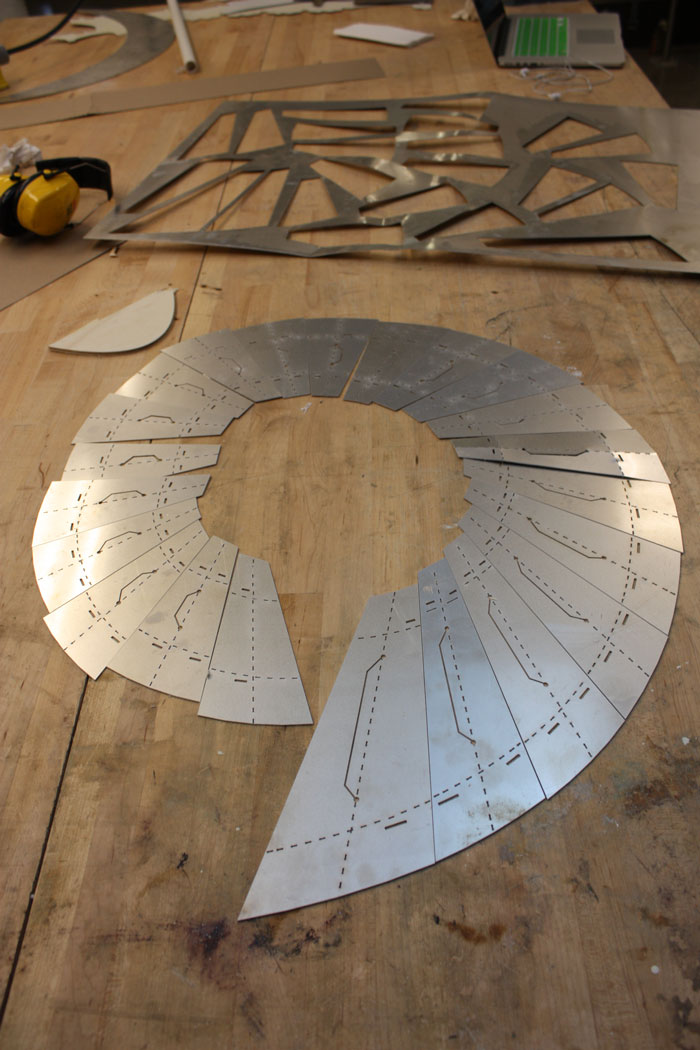

Exploration using waterjet frabrication process

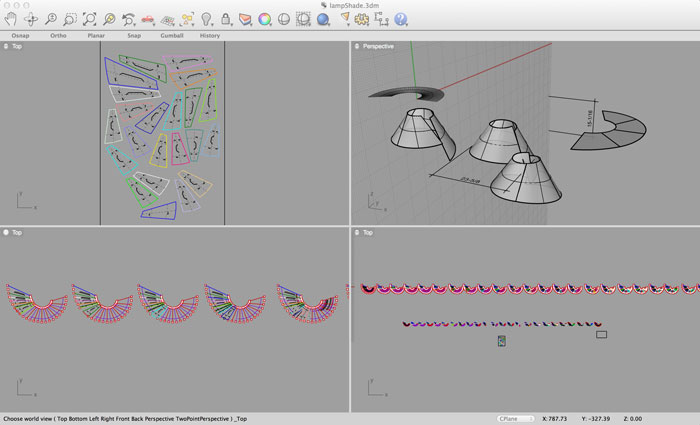

The goal in this project was to make a 3D surface using an aluminum sheet that is capable of adjusting its curvature. I looked at different systems that deal with this problem and evaluated how they negotiated a solution, and I ended up using the same logic that medieval armature makers used back in the days where coats of armor were not only beautiful but well crafted. This system consists of multiple flat surfaces that are scored, folded, and riveted together to create a curve. To make the fabrication process easier, the doubly curved surface of the torus was simplified into develop-able sections. These sections can be flattened and manipulated without greatly changing the original shape. I began by sketching the form in Rhino and once I had a shape that I was happy with, I used Rhino to unroll the digital surface and generate the files for laser-cutting. Each section was folded appropriately and then riveted to the previous section, producing the aluminum torus seen below.